Tiodize Company, Inc. – Advanced Coatings and Composites

Tiodize is an advanced technology company specializing in the development, manufacture and application of products for the prevention of friction, wear and corrosion. Our products are utilized in an increasingly broad spectrum of industries including aerospace, automotive, marine and electronics. In fact, almost any application that involves lubrication for friction and wear or corrosion barriers for galling and corrosion can benefit from Tiodize technology.

Long Beach Convention Center, California, USA

June 3-4, 2025

LEAD THE WAY IN SPACE

We’re thrilled to invite you to attend Space Tech Expo USA, taking place June 3-4 at Long Beach Convention Center, California. We will be exhibiting at the event as it is the perfect place for us to meet with valued partners, new connections and old friends – just like you.

This is the ideal chance for you to see our cutting-edge solutions live and up close as we meet face-to-face.

Join over 3,750 professionals as together we explore the future of the space industry.

Tiodize Composites

Tiodize Advanced Coatings

Green Products

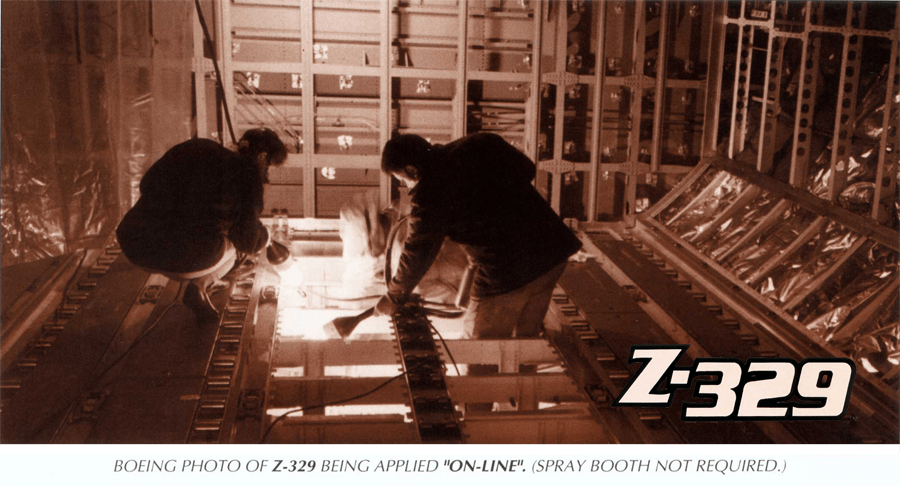

Z-329 Anti-Corrosion Coating

Low voc, non-flammable anti-corrosion coating.

Z-329 is a single component, water base coating formulated to inhibit corrosion . This hard film,water-dispersing coating is designed specifically for application on the interior and exterior surfaces of the fuselage, wing, empennage and other areas, where corrosion from water and condensation have been a traditional threat.

D99 Hand Sanitizer

JUST DEVELOPED BY TIODIZE TO HELP FIGHT COVID-19

- UNSCENTED FORMULA

- LEAVES NO RESIDUE

- DECREASES BACTERIA ON THE SKIN.

- RECOMMENDED FOR REPEATED USE.

FDA Registered: NDC: 77089-075-01, 77089-075-02 ,77089-075-03

INGREDIENTS: ISOPROPYL ALCOHOL, HYDROGEN PEROXIDE, GLYCEROL, AND PURIFIED WATER USP

ORDER # – 714-898-4377

Contact Tiodize

5858 Engineer Drive

Huntington Beach, CA 92649

Tel: (714) 898-4377

Fax. (714) 891-7467

Sales & General Information:

E-mail: tiodize@tiodize.com

The TIODIZE PROCESS is an electrolytic process using an alkaline bath which is maintained at room temperature. It produces anti-galling and wear resistant properties to the surface of titanium and its alloys, with no dimensional change.

FIBER/LITE® fasteners and fastening devices maintain high tensile, shear and fatigue strength at temperatures to 700°F and can be processed into a variety of signature free, non-corrosive shapes and sizes equivalent in strength to aluminum at two thirds the weight.

TRIBO/COMP® materials use graphite and kevlar® fibers combined with a resin and our proprietary lubricative pigments. TRIBO/COMP® materials are self-lubricating bearing materials with an unequaled wear life and a high strength to weight ratio.

HARDTUF® is an aluminum oxide coating for improving the hardness, lubricity and corrosion resistance of aluminum and aluminum alloys.

ALUMAZITE® is our family of aluminum pigmented coatings that prevent galvanic and environmental oxidation. Like our other anti-corrosion coatings, they have excellent adhesion qualities, are resistant to fluids and can be applied to a wide variety of materials.

TIOLON® is a family of PTFE (Teflon®) based lubricants designed for light loads, friction and wear surfaces as well as mold release applications.

In space applications, thermal control, EMISSIVITY and asorptivity are critical factors to the optimun peformance of a vehicle or satelite. Through years of research and work with various space agencies and manufacturers, TIODIZE has developed several processes and coatings to address these issues.

Contact Tiodize

Corporate Headquarters

5858 Engineer Drive

Huntington Beach, CA 92649

Tel: (714) 898-4377

Fax. (714) 891-7467

Sales & General Information:

E-mail: tiodize@tiodize.com