THE TIODIZE PROCESS:

TITANIUM ANODIZE

The TIODIZE PROCESS is an electrolytic process using an alkaline bath which is maintained at room temperature. It produces anti-galling and wear resistant properties to the surface of titanium and its alloys, with no dimensional change.

Fractures of both fatigue and tensile specimens show that there is NO HYDROGEN PICK-UP or hydrogen embrittlement; rather, there is an increase in fatigue strength due to the inherent complexity of the surface treatment by TIODIZE, which produces a finish that is an interstitial part of the metal itself.

- TIODIZE Type I is an electrically semi-conductive finish that is used as a pre-treatment for cold extrusion, hot forging and drawing operations, as well as a coating for absorptance and emittance.

- TIODIZE Type II provides an anti-galling surface and is an excellent surface preparation for dry film lubricants, paints and emissivity coatings.

- TIODIZE Type III is an entirely different process that produces a spectrum of surface colors on titanium, but does not offer anti-galling or wear resistance.

- TIODIZE Type IV is Type II with TIOLON X40 PTFE impregnated into the surface to provide low friction and anti-galling for longer life at higher loads.

The most complicated part configurations can be TIODIZED, including such difficult areas as blind holes and tubing walls. The throwing power of the solution gives continuous surface treatment, even in areas remote from the cathode. Contrasted with conventional plating, the process causes a “growth-inward” by the action of both solution and current. As a result, one of the most important advantages of the process is in the area of NO DIMENSIONAL CHANGE.

The TIODIZE PROCESS can be applied on all titanium surfaces.

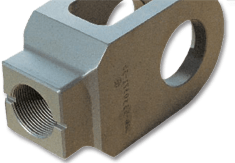

* Helicopter blade assembly clevis –

Tiodize Type II

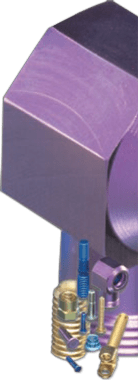

* Aircraft brake system component –

Tiodize Type II and Tiolube 460

TABLE OF CONTENTS

I. TIODIZE PROCESSES AND THEIR USES

- TIODIZE Types

- Use of the TIODIZE PROCESS

- Interference Fit Fasteners

- Improved Surface Finish -Titanium Turbine and Engine Blades

II. TEST RESULTS ON THE TIODIZE PROCESS

- Usage for Thermal Control: Insat-1 Domestic Satellite System for India

- Absorptance and Emittance Tests

- Vacuum Outgassing Test

- Comparative Fatigue Test

- Fatigue Tests

- LFW 1 Fretting Wear Tests

- LFW 1 Unidirectional Wear Test

- All Titanium Sliding Bearing Test

- Hypergolic Fluids Test

- Rocket Propellant Seal Test

- Titanium Actuator Test

III. SUPPLEMENT–TITANIUM DESIGN CONSIDERATIONS

- Basic Design Facts About Titanium and its Alloys

- Fabricating Properties of Titanium Alloys

Other Products by TIODIZE

TIODIZE, TIOLON, TIOLUBE, TICOMP, TRIBO/COMP, FIBER/LITE, RIV/LITE, CHANNEL/LITE, and ALUMAZITE are registered trademarks of TIODIZE CO., INC., Huntington Beach, CA 92649

Tiodize Type III

* Helicopter main rotor hub –

Tiodize Type II and Tiolube 460

Contact Tiodize Company, Inc.

Corporate Headquarters

5858 Engineer Drive

Huntington Beach, CA 92649

Tel: (714) 898-4377

Fax. (714) 891-7467

Sales & General Information:

E-mail: tiodize@tiodize.com