Composite Fasteners

Tiodize Advanced Products, made of Composite, for use with Composites. TIODIZE has developed a full range of FIBER/LITE® fasteners and fastening devices made of state of the art composites. These products maintain high tensile, shear and fatigue strength at temperatures to 500°F.

FIBER/LITE® fasteners and fastening devices

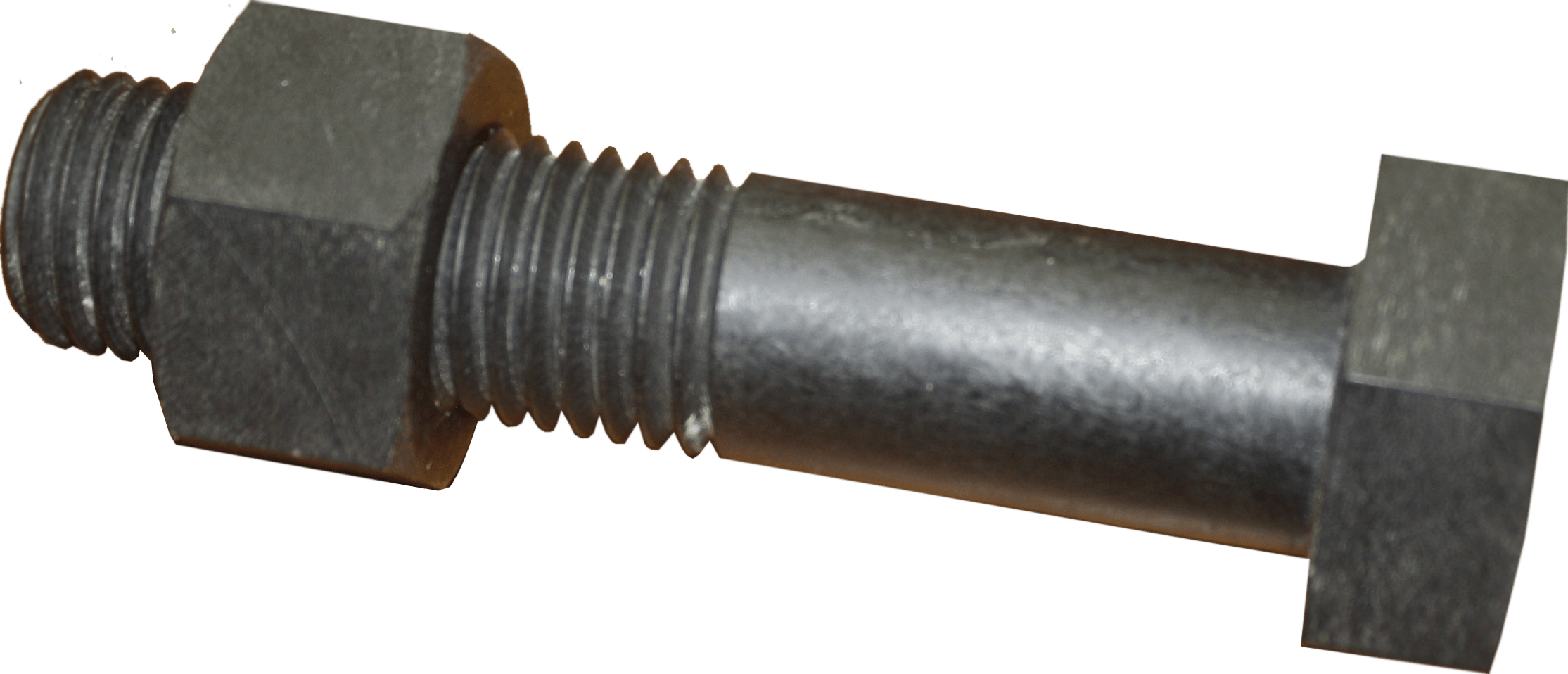

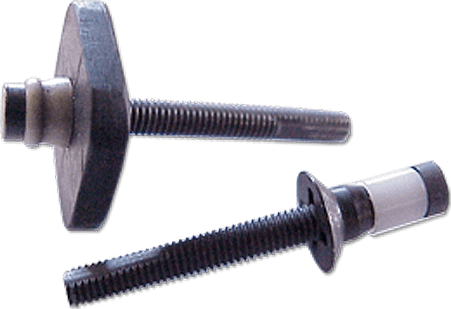

FIBER/LITE® can be processed into a variety of signature free, non-corrosive shapes and sizes greater than aluminum near one half the weight.

- Nuts

- Washers

- Rivets

- Latches

- Pins

- Inserts

- Hinges

- Hose Clamps

- Bolts

- Gang Channels

- Rod Ends

- Nut Rings

These components are manufactured by compression, matched-die molding and show excellent dimensional stability through repeated heating/cooling cycles and exposure to water or water vapor, solvents and oils.

** Contact the TIODIZE Engineering Department to review your drawings and specifications. We look forward to working with you to develop composite parts that meet your requirements.

LEGEND:

SL= SELF LOCKING MT= MODIFIED THREAD PLFC·7= 1M 7 FIBER PLFC= AS·4 FIBER G= GLASS (52) C=CARBON

| FIBER LITE MATERIAL PROPERTIES | ECFG | PLFG | PLFC |

| Density | 1.81-1.85 g/cm³ 0.65-0.67 lb/in³ | 1.95·2.00 g/cm³ | ~1.5 g/cm³ |

| Flexural Strength | 58,00 psi | ||

| Flexural Modulus | 2.6x10⁶ | ||

| Tensile Strength at (75° F) | 33,000 psi | 45,000 - 53,000 psi | 50,000 - 97,000 psi |

| Tensile Strength at (-320° F) | 22,00 psi | ||

| Compressive Strength at (75° F) | 33,000 psi | 33,000 psi | 33,000 psi |

| Compressive Strength at (300° F) | 10,400 psi | ||

| Double Lap Shear Strength | 30,00 psi | ||

| Single Shear | 40,000 psi | 50,000 psi | |

| Continuous Use Temperature (1000 hours) | 400° F | 500° F | 500° F |

| Coefficient of Thermal Expansion | 7x10¯⁶ in/in/ °F | 4-11x10¯⁶ in/in/ °F | 1x10¯⁶ in/in/ °F |

| Water Absorption (24 hrs @23) | 0.0008 | 0.0011 | 0.0005999999999999999 |

| Thermal Conductivity | 6.8x10¯⁴(cal/sec-cm² C/cm) | 8x10¯⁴(cal/sec-cm² C/cm) | 2-3x10¯⁴(cal/sec-cm² C/cm) |

| Volume Restrictivity | >3x10¹⁴ohm-cm | 10¹⁶ohm-cm | Conductive |

| Dielectric Strength | 500V/mil | 450V/mil | Conductive |

| Dielectric Constant (100hz) | 4.3 | Conductive | |

| Dielectric Factor (100hz) | 0.007 |

AS MOLDED TEST

| Bolt | Nut | Thread | Tensile load (LB5) | PSI (AVG) |

| PLFG | TI/PMFG/SL | 10-22MT | 955 | 53330 |

| PLFG | PMFG/SL | 10-22MT | 942 | 52603 |

| METAL | PMFG/SL | 10-22MT | 1723-1684 | 95130 |

| PLFC-7 | ECFG | 10-22MT | 1300-1401 | 75410 |

| PLFC-7 | TI/PMFG/SL | 10-22MT | 1705 | 95210 |

| METAL | ECFG | 10-22MT | 1229-1297 | 70530 |

HOT WET TEST

| Bolt | Nut | Thread | Tensile Load (LBS) | Tensile Strength PSI | Change In Strength |

| PLFG | Tl/PMFG/Sl | 10-22MT | 614 | 34,290 PSI | -0.357 |

| PLFG | PMFG/Sl | 10-22MT | 628 | 35,070 PSI | -0.333 |

| Metal | PMFG/Sl | 10-22MT | 1421 | 79,350 PSI | -0.166 |

| PLFC-7 | ECFG | 10-22MT | 1243 | 69,410 PSI | -0.08 |

| PLFC-7 | Tl/PMFG/Sl | 10-22MT | 1729-1759 | 97,330 PSI | 0.021 |

| Metal | ECFG | 10-22MT | 1237-1264 | 69,830 PSI | -0.01 |

Developed and Manufactured by: TIODIZE Co., Inc. – Protected by U.S. and Related Foreign Patents

Contact Tiodize Company, Inc.

Corporate Headquarters

5858 Engineer Drive

Huntington Beach, CA 92649

Tel: (714) 898-4377

Fax. (714) 891-7467

Sales & General Information:

E-mail: tiodize@tiodize.com