Our materials have a high strength-to-weight ratio which is one-fourth the weight of steel and two-thirds the weight of aluminum. These graphite composites exhibit extremely long wear life, low coefficient of friction (as low as .07) and will withstand loads in excess of 30,000 psi. They will also have chemical inertness and good electrical and thermal conductivity.

TRIBO/COMP can be processed into a variety of mechanical shapes which are self-lubricating and are superior to aluminum in stiffness per unit mass at temperatures to 600°F These components are manufactured by compression, matched-die molding and show excellent dimensional stability through repeated heating/cooling cycles and exposure to water or water vapor, solvents and oils.

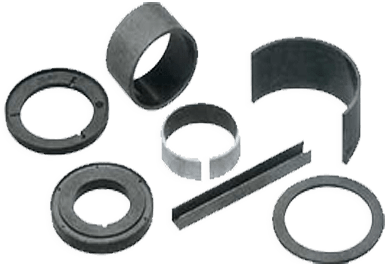

TRIBO/COMP can be made in many shapes and forms such as:

- Spherical Bearings

- Rod End Bearings

- Bushings

- Stem Guides

- Thrust Washers

- Wear Pads

- Vanes

- Pistons

- Slide Bearings

- Bearing Retainers

- Gears

- Seats

** Contact the TIODIZE Engineering Department to review your drawings and specifications. We look forward to working with you to develop composite parts that meet your requirements.

TRIBO/COMP®

VS.

Steel & Titanium

Friction/Wear

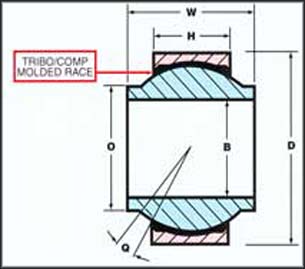

| BEARING NUMBER | B BORE DIA +.0000 -.0005 | D OUTSIDE DIA +.0000 -.0005 | W BALL WIDTH +.000 -.002 | H RACE WIDTH+.005 -.005 | O SHOULDER DIA MIN | BALL DIA REF | RADIAL DYNAMIC LOAD RATINGS (LBS) | Q° APPROX MISALIGN- MENT | STATIC LIMIT LOAD | APPROX WEIGHT (LBS) | NO LOAD BREAK AWAY TORQUE (IN-LBS) | |

| RADIAL (LBS) | AXIAL (LBS) | |||||||||||

| -12 | .7500 | 1.5625 | 1.280 | .620 | .970 | 1.375 | 22,800 | 20° | 47,000 | 10,400 | 0.31 | 0-15 |

LEGEND:

PMFC= PEEK resin, Milled Fiber, Carbon

RMFC= Polyimide resin, Milled Fiber, Carbon

PMFK= PEEK resin, Milled Fiber, Kevlar

| Tribo/Comp Material Properties | PMFC (Carbon) | RMFC (Carbon) | PMFK (KEVLAR) |

| Compressive Strength psi | 35000 | 35000 | 35000 |

| Tensile Strength psi | 24000 | 24000 | 20000 |

| Punch Shear psi | 15000 | 15000 | 12000 |

| Coefficient of Thermal Expansion | ************* | ************* | ************* |

| µ in/in/F | >350°F | ||

| Direction of Compression | 30 | 6.5 | |

| Perpendicular to Compression | 7 | 2.5 | |

| Average <350°F | 8 | ||

| Coefficient of Friction (vs Steel) | 0.15 | 0.15 | 0.15 |

| Coefficient of Friction (vs Titanium) | 0.17 | 0.17 | 0.17 |

| Wear Rate mils/1000 ft | ************* | ************* | ************* |

| At PV=1,600,000 | 0.35 | 0.29 | 0.58 |

| At PV=300,000 | 0.028 | 0.047 | 0.042 |

Developed and Manufactured by: TIODIZE Co., Inc. – Protected by U.S. and Related Foreign Patents

Contact Tiodize Company, Inc.

Corporate Headquarters

5858 Engineer Drive

Huntington Beach, CA 92649

Tel: (714) 898-4377

Fax. (714) 891-7467

Sales & General Information:

E-mail: tiodize@tiodize.com